HOW THIS ORGAN CAME TO BE RESTORED

I was first contacted about restoring this Bell reed organ by Mark Jefford who was the regional representative of the American Reed Organ Society for Ireland and the UK. Mark emailed all reed organ enthusiasts in the region in March 2013. The granddaughter and niece of the organist, who played the organ in Mullafarry Presbyterian Church in Killala, Co. Mayo in the 1920's, wanted it restored. It was in storage in a disused farm house since the early 2000’s. I volunteered to visit Mullafarry to make an assessment of the organ and the restoration required. Since I was in the process of completing the restoration of the Smith Connoisseur organ I was unable to visit until July 6th 2013.

SPECIFICATIONS

This reed organ was made by the Bell Organ and Piano Company of Guelph Canada circa 1897. The case is made of walnut.

The organ has 14 stops. There are three sets of reeds, one 16ft pitch, one 8ft pitch and one 4ft pitch. It is tuned to A454.

Stop list starting left to right:

Viola 4ft, Diapason 8ft, Dulcet 8ft (Soft version of Diapason 8ft), Bass Bourdon 16ft, Bass coupler, Vox Humana, Forte, Treble coupler, Cremona 16ft (Soft version of Cello 16ft), Cello 16ft, Dulciana 8ft (Soft version of Melodia 8ft), Melodia 8ft, Viol D'amor 4ft (Soft version of Vox Angelica 4ft), Vox Angelica 4ft

It is a 61 note keyboard with 183 reeds. The keyboard is divided at A/A flat below middle C.

The Forte stop acts on the 4ft and 16ft rank of reeds only. The knee-swell acts on all three sets of reeds.

Due to the wood worm infestation and evidence of fresh activity I decided not to take it home until the end of September when the worm would be dormant. I picked up the organ on the 28th of September 2013. On arrival for pick up the organ was waiting outside ready. When moved, the entire pedal assembly collapsed and was left hanging on by the straps.

DISASSEMBLY

When I got the organ home and began the disassembly large parts of the front of the case became detached entirely. The back cover was badly warped, riddled with lots of woodworm and needed to be replaced. The wooden casters were seized and worn. There was a crack in the lid.

The bellows and bellows platform were so infested with worm that the layers of plywood delaminated completely. Someone had tried to give new live to the bellows at some stage by covering it with upholstery leatherette. This solution was never going to be very successful. It was obvious that a new bellows and bellows platform were required.

As mentioned, many of the stop faces were lost. The Vox Humana mechanism long since seized. The key fronts were all loose and some missing. There were remnants of a 'damp chaser' device attached to the reed pan. Springs were broken on mutes and swell shades. Generally, as is expected in these instruments, it was absolutely filthy.

Click on images below to enlarge.

Click on images above to enlarge.

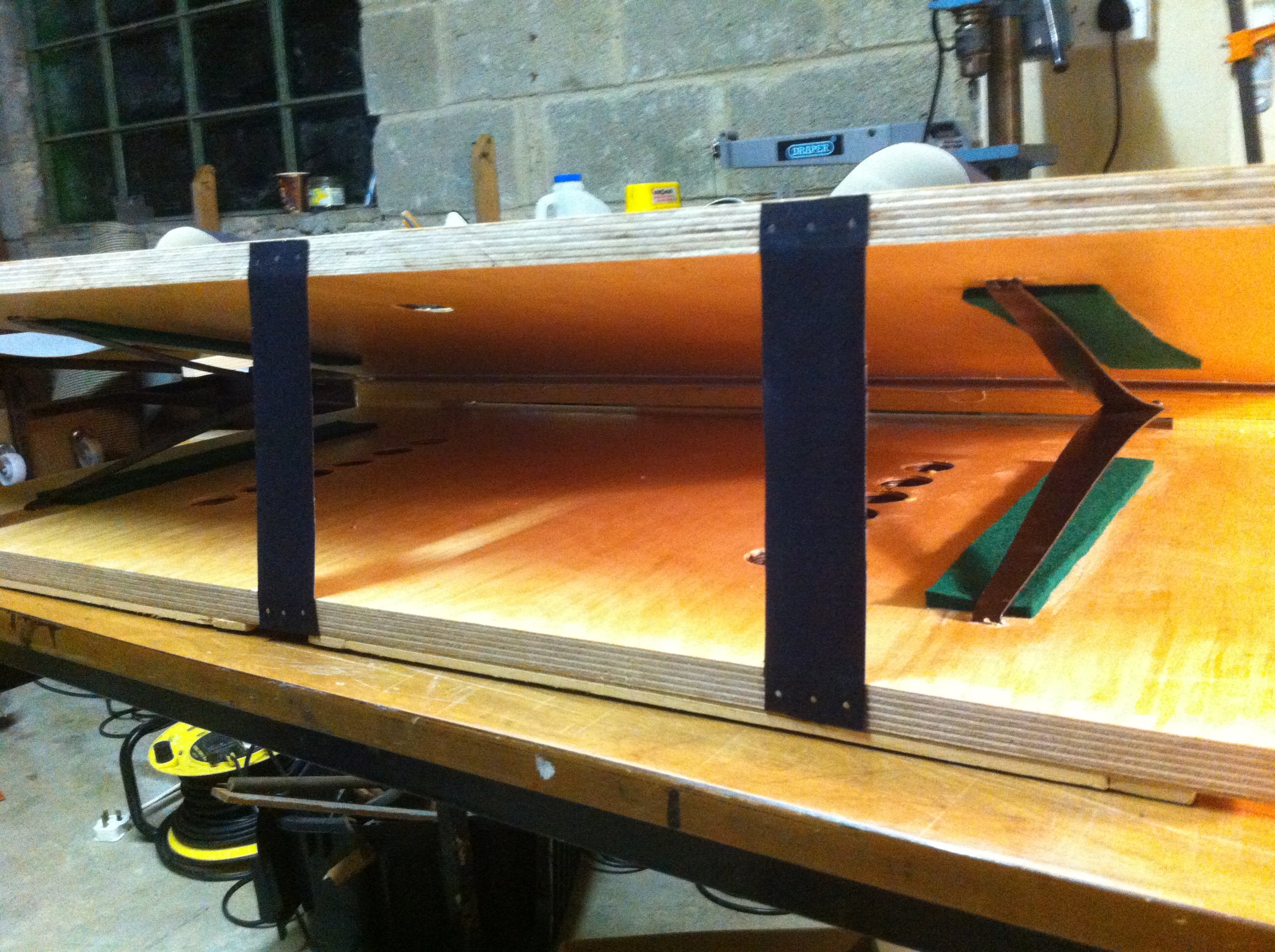

BELLOWS RESTORATION

Making a new bellows and bellows platform is not as difficult a task at it might first appear. A bellows is made up of square and rectangular sheets of wood. In this restoration high quality 18mm birch plywood was used. The original was 15mm but that is not available so the next best thing is fine. That's ok for the bellows but for the bellows platform it is not. If thicker than 15mm is used it raises the entire upper action and has a serious knock on effect in many ways. The options were to have three 5mm sheets laminated together or to router out a track in the 18mm in which the reed pan would sit. I chose the latter. It has worked very well. The original pieces of the dilapidated bellows and platform were used as a template and general guide. The bellows was covered with genuine rubberised bellows cloth from Schaff Piano Supply Company, Lake Zurick, Illinois. The straps were replaced. Only genuine animal hide glue was used.

Vox Humana

The Vox Humana is a fan which causes a tremolo effect on the 16ft and 4ft reeds when selected. The Vox Humana mechanism was completely dismantled and cleaned. Some of the vanes in the turbine were cracked or broken. These were replaced using thin softwood. The card blades were replaced using similar grade card. The felt bushings were replaced. An upgrade to the original method of assembly here was the replacement of the nails in the end panel with small brass counter-sunk screws. This will allow for easier servicing in the future. Leather gaskets were replaced. The screw holes where the Vox Humana attaches to the reed pan had enlarged so they were drilled, plugged and new holes drilled.

Stop board

The stop board was completely dismantled. All shafts were sanded and repainted in gloss black. The leathers were replaced and lubricated with graphite. The stop knobs were sanded and painted. Some of the fronts were missing and were replaced using the donor organ. Felt was replaced throughout; all linkages were cleaned and polished.

At first it was not clear if the original decals could be saved. The name board was in bad condition. Using advice from Rodney Jantzi in Canada I sanded the board, touched it in with matt black paint and varnished it.

Rodney Jantzi very generously donated a whole set of stop labels from an old Bell organ and sent several more spares, as a result stop labels could be replaced using vintage originals. Determining the correct fronts was done by determining rank pitch and referencing the Reed Organ Society database of other Bell reed organs. It was also easy to recognise function of couplers, Forte, and Vox Humana.

Keyboard

The keys were badly worm eaten; not uncommon since they are always made from very soft light wood. I treated them with Cupernol Wood Worm treatment and then sealed them in plastic bags and put them in the freezer for three weeks to make sure the worm was dead.

All the celluloid key fronts were loose and some were lost. One key top was damaged and needed replacement. All fronts were removed, sanded and glued back in place. All keys were polished. The sharp keys are of walnut and needed to be polished and part painted black. All keys were sanded (except 3, explanation below). All keys had their under felt replaced and were re-bushed using woven bushing cloth from Schaff Piano Supplies.

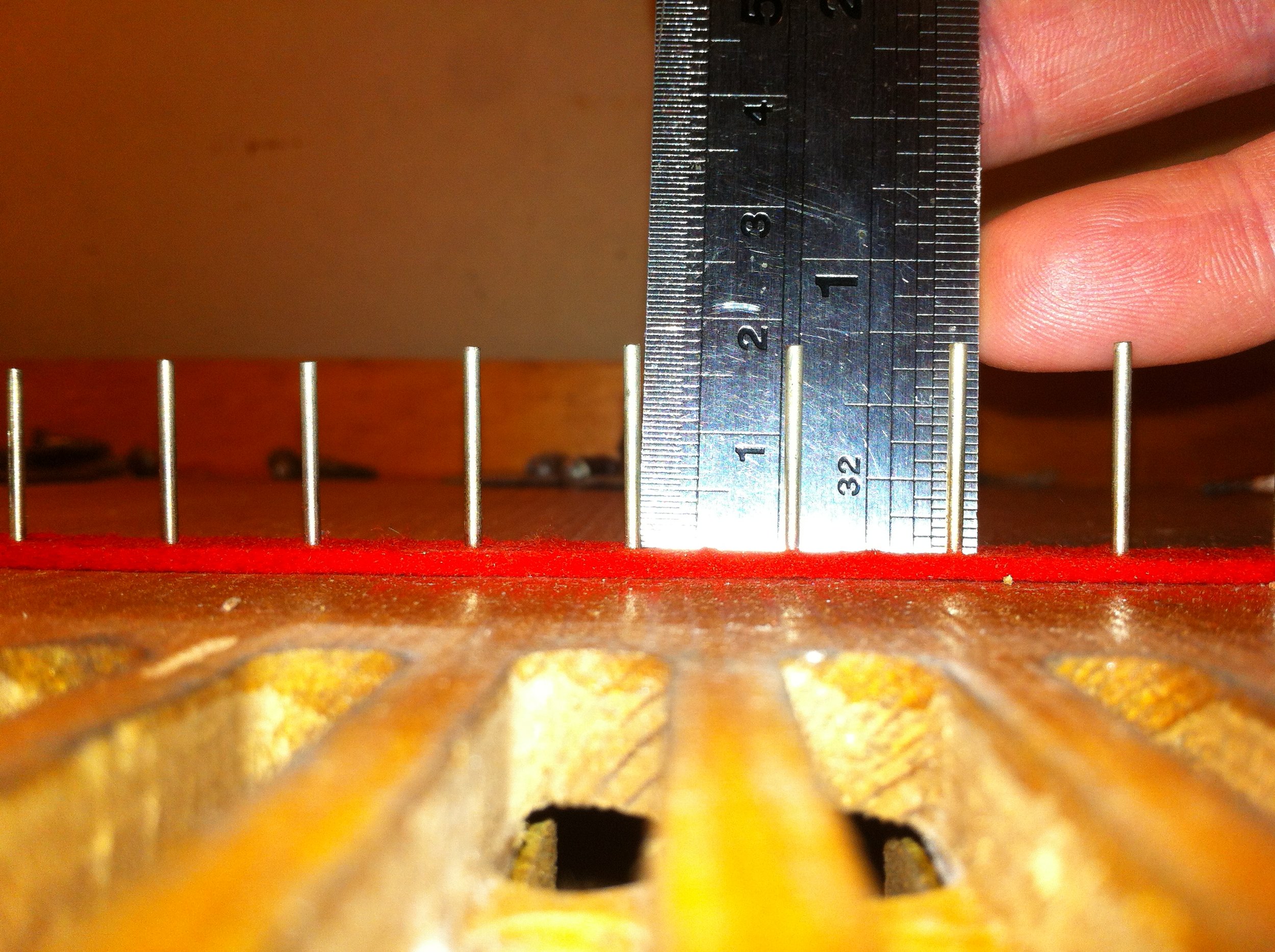

The key frame was stripped and cleaned. All brass guide pins were removed, cleaned and polished to ensure smooth operation of the keyboard.

The keyboard was meticulously levelled using small card disks and fish glue.

I refrained from sanding three keys because they contained a pencil signature of the tuner of the reed organ.

CONDITION REPORT

Upon first viewing it was clear that the organ was in very poor condition – I had scrapped better – but none the less restorable. The original information was that, 'the stops and knee levers need attention'. Quite an understatement!

It was infested with wood worm, riddled with damp and the stop faces were all missing bar four or five. The oil lamp stands were missing from the side and it had a contrived music desk attached constructed from aluminium strips and a Mason and Hamlin reed organ music desk. There were many reasons not to restore it but I couldn't ignore the enthusiasm of Diane Kelly to see the instrument returned to the church where it was once played by her grandmother. So I decided to restore it.

A really fortunate turn of events in the restoration of this organ was the donation of another dilapidated organ for parts by a parishioner, Avril Murphy. Fortunately this organ was also a Bell so it was able to yield valuable parts as a 'donor organ'. Most importantly, the oil lamp stands which were missing, could now be replaced.

CASE RESTORATION

The first part of the restoration of the case required copious amounts of Cupernol wood worm treatment. The next part of the restoration was basic structural repairs to the case. The pedal assembly was rebuilt. The parts were 'biscuit jointed' back together and the central rail which was missing was replaced using one from our Bell 'donor organ'. The pedals were stripped of their old carpet.

The front parts of the case were also 'biscuit jointed' back together. This method gives a good and lasting stable joint. Originally, the parts were just butted up against each other and glued. The back rail on the bottom of the organ was eaten by something which left a 2mm exit hole. Frightening! It was taken off and burned immediately. It was replaced by a solid piece of oak - nice upgrade from just soft wood.

Originally this organ had three wooden casters; on each of the front corners and a single one in the middle back. Since they were seized and needed to be replaced I took the liberty of replacing them with four casters. As a result there is now a caster on each corner with a more even distribution of weight.

The Pedals

The pedals were stripped of their old carpet and metal hardware. New carpet was applied and the metal work stripped, primed and painted. The Pedals are marked as ‘Mouse Proof’. An innovation to make the organ attractive in a market flooded with reed organs.

The Upper Action

Reed pan

When the entire upper action was stripped down the rebuild started with the reed pan. This was cleaned, sanded and shellacked. New reed-bed felt was applied. The holes for the 'damp chaser' were drilled and plugged. All reed cells were thoroughly brushed out. The pallet valve guide pins and pallet valves were all removed and polished. This will ensure smooth movement of the pallet valves.

Pallet valves

Pallet valves are the valves which open when a key is depressed. They were all stripped of their old felt and leather and new felt and leather applied. These are then returned to position.

Pitmans

Pitmans are the dowels which connect the keys to the pallet valve. All pitmans were cleaned, re-felted and re-graphited before being reinstalled.

Reeds

All reeds were removed and carefully kept in order so they could be replaced in their original position. They were cleaned using an ammonia based clock cleaning fluid in an ultrasonic cleaner and finished off with fine grade wire wool. A tedious task where each reed is polished individually.

All reeds were tuned to A454 - this was the very last job completed.

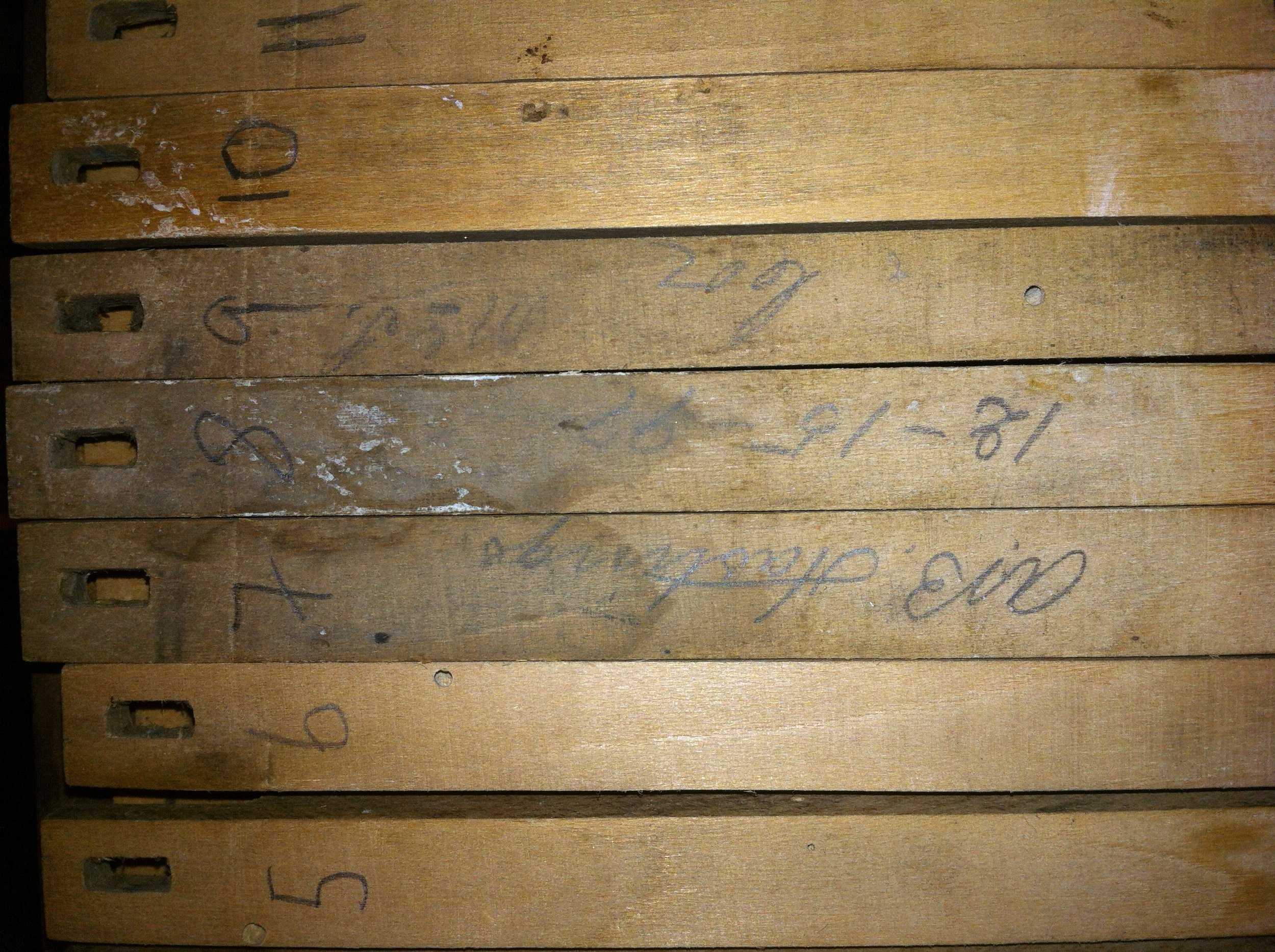

The reeds are stored before cleaning in rank and sequence, on masking tape, rolled up with a paper layer to protect the tongues.

Mutes

Mutes are the valves which cover each rank of reeds in both the bass and treble register. When opened, by pulling a stop, they allow a rank of reeds to sound. These had their old leather removed, hinges polished and springs replaced.

Swell shades were stripped, hinges and springs replaced and shellacked.

Knee Swell and Great Organ Mechanism

All parts of the swell and great organ mechanism were re-felted. Some of the wood was so badly eaten that it required filling before felt was applied. Badly rusted screws were replaced. The holes in the linkages were drilled and plugged to receive their new screws. All retainers were sanded, bushings were replaced, metal linkages polished and graphite applied where necessary.

Coupler Mechanism

The coupler mechanism is a system of rods which, when selected, link a key with the corresponding key an octave above in the treble or below in the bass.

The coupler was particularly dirty since it is located directly under the keyboard. All the felt bushings were worn or eaten away and the retaining clips were badly rusted. Many replacements had to be handmade.

Click on images to enlarge